Cryolite flash drier, is my factory on the basis of introducing and absorbing foreign advanced technology, successfully developed new type of Drying equipment. This advanced technology, reasonable design, compact structure, wide applicable scope, large production capacity, products of good quality and high efficiency, energy saving, within a equipment drying, crushing, screening a one-time, eliminate the pollution of the environment, the whole machine performance reached the international advanced technology level.

Cryolite drier principle:

Hot air by inlet tube enters from bottom of drier with suitable spouted velocity stirring drying chamber size, the material to produce strong shearing, blowing floating, rotating, so the material by centrifuge, shearing, collision and friction, and dividend particulates reinforced heat transfer and mass transfer. At the bottom of drier, is bigger than the wet particles under the action of stirrer is mechanical crushing, low moisture content, the smaller the particle size, particle entrainment by the rotating flow increase, rising into the step in the process of drying. Because of gas-solid two phase rotating flow, solid phase of inertia is greater than the gas phase and two phases of gas in the relative velocity is larger, strengthen two heat transfer and mass transfer, so the machine production of high strength.

Cryolite drier features:

A variety of feeding device to choose, continuous and stable feeding, process won't produce bridge phenomenon in the middle.

Set up the special cooling device at the bottom of the drier, avoids the phenomenon of material at the bottom of drier metamorphism.

Low special pressure seal and bearing cooling device, effectively prolong the service life of transmission parts.

Special air distributing device, reduces the equipment resistance, and effectively provides a dryer Handled Wind quantity.

There are rotation flow pieces and low drying chamber is equipped with grading ring, adjustable fineness and raw material. (such as calcium carbonate water regulator to 0.1% or less)

Low relative to other drying method, which can effectively increase the proportion of the material.

Low dry indoor circumferential High gas velocity, the material stay time is short, effectively prevent and metamorphic thermal sensitive material phenomenon of wall material viscosity and achieve High efficient, fast, and small equipment, mass production.

To adapt to the material:

Low categories: inorganic borate, calcium carbonate, hydroxide, copper sulfate, ferric oxide, barium carbonate, antimony trioxide, all kinds of metal hydroxide, all kinds of heavy metal salt, synthetic cryolite and so on.

Low organic matter: atrazine (pesticides), lauric acid, benzoic acid, benzoic acid, sterilization, Dan, sodium oxalate, cellulose acetate, etc.

Low ceramic kaolin clay, silica, clay.

Low dye categories: anthraquinone, black ferric oxide, indigo blue Pigment, butyric acid, titanium hydroxide, zinc sulfide, all kinds of azo dye intermediates.

Low food: soy protein, starch gel, grains, wheat, sugar, wheat starch.

|

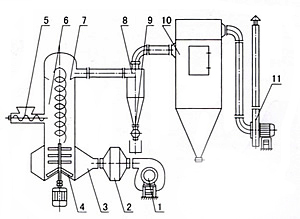

1. blower

|

7. classifier

|

|

2. Heater

|

8. cyclone

|

|

3. The air distributor

|

9. Star unloader

|

|

4. Mixer

|

10. The bag filter

|

|

5. Add the spiral classifier

|

11. The draft fan

|

|

6. Dryer

|

|

|

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us