Product details

A, equipment principles:

Paddle type drier is a kind of low heat conduction speed mixing type drier. Set on the dryer cylinder jacket, hollow shaft is set on the hollow paddle, in which the heat carrier, wet material cylinder under the agitation of the stirring paddle and paddle sufficient hot surface heat exchange, in order to achieve the purpose of drying. It has small and large heating area per unit volume, the advantages of high thermal efficiency. It absorbs the foreign paddle drying technology, using the wedge and disc two paddle forms, and toxic sludge use the different disposal forms such as vacuum or high vacuum.

Second, features:

1. The dryer is a kind of small volume, high efficiency of dryer, heat transfer efficiency > 75%.

2. The heat transfer medium in the form of steam or heat conducting oil, the cavity temperature control under 200 ℃, no dust explosion hazard.

3. The material in the dryer after paddle mixer, endothermic, crushing.

4. The seal design easy to collect waste Handled.

5. Continuous production, reduce labor.

6. Material selection Q235A, manganese steel, ordinary stainless steel, duplex stainless steel, etc.

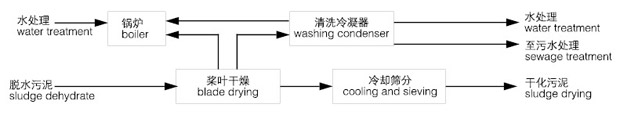

The process flow

(1) feed. With screw conveyor solid content of 15% to 15% of the import of dewatered sludge sent to dryer, sometimes according to the properties of the sludge. Choose whether to screening good small dry sludge and sludge to stay dry premixed.

(2) the heat source. You can use hot steam or hot oil as a heat source of heat. General thermal fluid temperature of 180 ℃ to 180 ℃. Heat medium respectively was introduced into hollow and rotating shaft paddle drier shell and all contact with the sludge heat exchange of heat the metal surface.

3) the sludge drying. Metal surface contact with the sludge evenly heating, heating evaporation of moisture in sludge, sludge along the axial length of drier, water vapor goes through a constant rate of evaporation and low evaporation rate in two stages, sludge drying plasticizing, broken plastic, block, particle four steps, the temperature of the sludge is rising fast, stable, rapid rising trend, finally export sludge temperature about 100 ℃ to 110 ℃, export sludge solids content above 90%.

(4) cooling sieve. Have a direct and indirect cooling cooling cooling in two ways, two ways to access to the fine screen for screening, or after building type machine to achieve the required dry sludge shape.

(5) the condensate recovery. Sent to the condenser heat steam condensation within the dryer Handled, condensation solvent recovery, not condensate gas boiler heating again to the heat source, condensed water back Handled sewage plant.

|

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us