Brief:

Chinese medicine extract special spray drier to absorb foreign technology is applicable to the development of low melting point, high sugar content of Chinese medicine products Drying equipment. The device determines the drying spray-dried product according to the characteristics and nature of the process conditions, a high degree of automatic, easy to operate, meet the GMP requirements. The successful development of the device, many years to solve the low melting point, high sugar content of Chinese medicine products can not be spray dried technical difficulties, but also the development of new spray-drying in the Chinese pharmaceutical industry applied technology research.

working principle:

Chinese medicine extract high-speed centrifugal spray device is centrifugal spray drying technology in particular material drying, but also high-speed centrifugal atomization allows material dispersed into a fine, full contact with the hot air to complete the instant drying to form a powder finished drying apparatus. The Drying equipment is designed to solve the Chinese medicine extract and plant extract spray drier, which effectively solve the original LPG high-speed spray drier appear in Chinese medicine extract drying problems, compared with the original LPG centrifugal spray drier there the following characteristics:

1, in order to prevent the matter Branch sticky wall generating device is provided with an air sweep wall tower wall jacket cooling structure, effective way to eliminate the sticky wall coking products. Improve product quality and yield.

2, ZLPG series Traditional Chinese medicine extract spray drier may be unique wind supply system, separated in time and finished drying wet air heat system, avoid moisture resurgence of agglomeration of the finished produce.

3, enter ZLPG series Traditional Chinese medicine extract spray drier air three-stage air purification, the inlet air to reach 300 000 requirements;

4, ZLPG series Traditional Chinese medicine extract spray drier using the quick opening punch election means for varieties production requirements;

5, two-stage cyclone dust collecting material means or a cyclone + wet scrubber;

6, spray tower size and configuration for applicability was adjusted according to the nature of families, making it more practical;

7, ZLPG series Traditional Chinese medicine extract spray drier can choose PLC control, program control system screen display;

8, the entire drying system design meet the requirements of GMP;

9, users can choose the order was based on A type of Cote, B type, C type, one of which was to achieve the best adaptive equipment and between families.

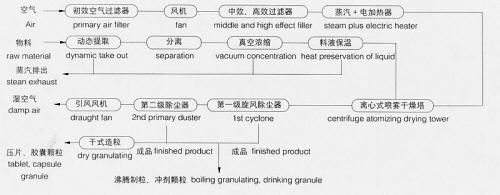

Process:

Technical Parameters:

|

Model

|

ZLPG-5

|

ZLPG-10

|

ZLPG25

|

ZLPG-50

|

ZLPG-80

|

ZLPG100

|

ZLPG-150

|

ZLPG-200

|

ZLPG-300

|

|

Water evaporation (kg / h)

|

5

|

10

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

Handled liquid feed amount (kg / h)

|

6-7

|

12-14

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

Finished output (kg / h)

|

1-2

|

2-4

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

28-42

|

36.8-56.4

|

55-85

|

|

Wet materials containing solid content (kg / h)

|

18-25

|

|

Moisture percentage (%)

|

3-5

|

|

Electric power (kw)

|

36

|

45

|

63

|

99

|

132

|

153

|

204

|

246

|

330

|

|

Heating source

|

Steam Electric Steam plus electricity +

|

|

Products popular way

And efficiency

|

Two cyclone or a cyclone and a wet scrubber ≥95%

|

|

Controlled instrument

|

Hot air temperature and exhaust temperature indicator, automatic control meters and instruments

|

|

Inlet air temperature (℃)

|

150-200

|

|

The air temperature (℃)

|

80-100

|

|

Dimensions

(Mm)

|

Long L

|

5000

|

5500

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15,000

|

|

Width W

|

3000

|

3500

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

High H

|

4500

|

4600

|

5200

|

6500

|

7600

|

8100

|

9000

|

9850

|

11100

|

|

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us