Brief

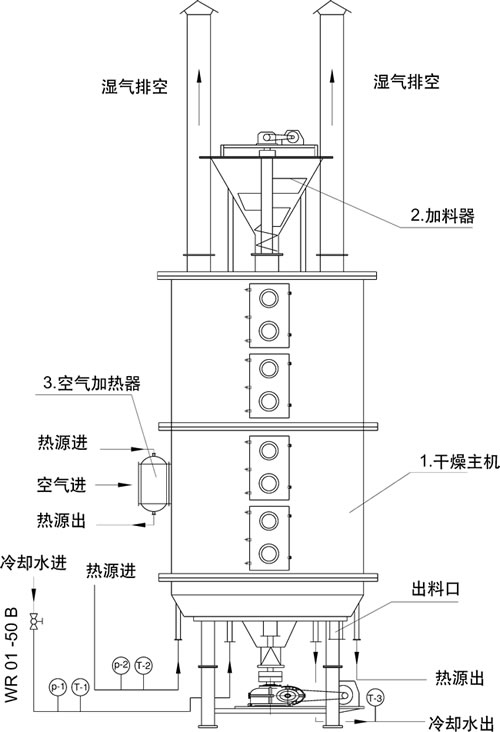

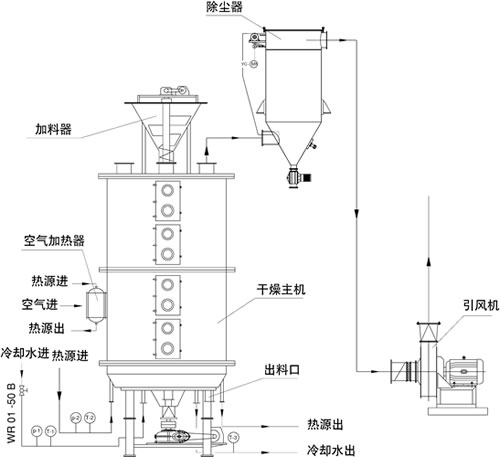

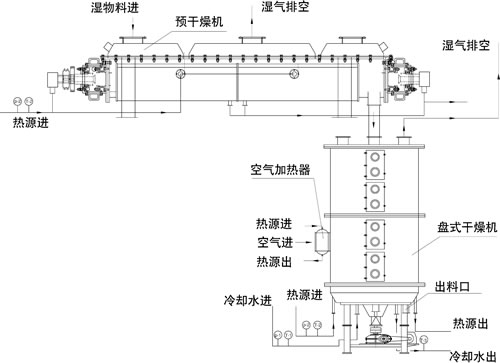

PLG series Disk continuous drier is a High efficient conduction type continuous Drying equipment. Its unique structure and operating principle determines that it has high thermal efficiency, low energy consumption, Floor area of small, simple configuration, convenient control, good operating environment and other characteristics, widely used in chemical, pharmaceutical, pesticide, food, feed, agricultural products processing industries drying operation. Well received in various industries practice. Now manufacturing pressure, sealed, vacuum three categories of type, 1200,1500,2200,3000 four kinds of specifications, A (carbon steel), B (contact material part of the uniform stainless steel), C (on the basis of B on the increase steam pipes, stainless steel main shaft and support, lined with stainless steel barrel and cap top). Three materials, Dry area 4 ~ 180m2, a total of several hundred Model of series products, and can provide a matching types of auxiliary equipment, users can meet the needs of a variety of materials to dry.

Feature

(A) easy to adjust, applicability

1, by adjusting the thickness of material, spindle speed, the number of target arm, leaves the target type style and size of the drying process to achieve the best results.

2, PLG series Disk continuous drier Each layer of drying plate can be led solely by the medium or cold medium, the material for heating or cooling, the material temperature control is accurate and easy.

3, the residence time of the material can be accurately adjusted.

4, the flow of material First single, non-back-mixing, even drying and stable quality, no re-mixing.

(B) simple, easy

1, dryer car parking operation is very simple.

2, stop feeding, the scale of the target transfer material leaves can quickly emptying the dryer by.

3, through large glass viewing window specifications, can be carried out within the device very carefully cleaning and observation.

(C) low energy consumption

1, the material layer is thin, low spindle speed, material delivery system needs small power, less power consumption.

2, by conducting heat drying, high thermal efficiency, low energy consumption.

(Iv) operating environment, recyclable solvents, dust emissions to meet the requirements

1, atmospheric type: Due to the device is a low air velocity, and humidity distribution within the device Gao low, dust is difficult to float to the top of the device, so the top of the exhausts from the outlet of the exhaust gas contains almost no dust.

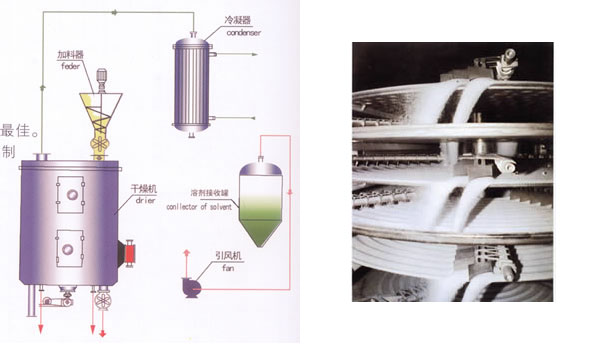

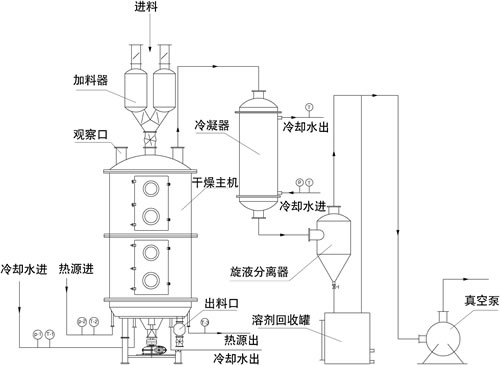

2, the sealing type: equipped with solvent recovery device, can be easily recycled wet gas contained in an organic solvent economy. Solvent recovery is simple, high recovery rate for flammable, explosive, toxic and easy oxidation of materials that can be used wet nitrogen as the carrier gas in closed loop, so that safe operation, especially for flammable, explosive, toxic materials dry.

3, vacuum type: Disc dryer under vacuum state operation, especially suitable for drying heat sensitive materials.

Convenience (e) the installation, Floor area small

1, PLG series Disk continuous drier overall factory, the overall transport, simply hoisting, positioning is very easy to install.

2, since the drying plates being arranged by layers, vertical installation, even great Dry area, Floor area is also very small.

Technical Parameters

| specifications |

Outer diameter |

Height |

Dry area m2 |

Power Kw |

specifications |

Outer diametermm |

Height mm |

Dry area m2 |

Power Kw |

| 1200/4 |

1850 |

2608 |

3.3 |

1.1 |

2200/18 |

2900 |

5782 |

55.4 |

5.5 |

| 1200/6 |

3028 |

4.9 |

2200/20 |

6202 |

61.6 |

| 1200/8 |

3448 |

6.6 |

1.5 |

2200/22 |

6622 |

67.7 |

7.5 |

| 1200/10 |

3868 |

8.2 |

2200/24 |

7042 |

73.9 |

| 1200/12 |

4288 |

9.9 |

2200/26 |

7462 |

80.0 |

| 1500/5 |

2100 |

3022 |

8.0 |

2.2 |

3000/8 |

3800 |

4050 |

48 |

11 |

| 1500/8 |

3442 |

10.7 |

3000/10 |

4650 |

60 |

| 1500/10 |

3862 |

13.4 |

3000/12 |

5250 |

72 |

| 1500/12 |

4282 |

16.1 |

3.0 |

3000/14 |

5850 |

84 |

| 1500/14 |

4702 |

18.8 |

3000/16 |

6450 |

96 |

| 1500/16 |

5122 |

21.5 |

3000/18 |

7050 |

108 |

13 |

| 2200/6 |

2900 |

3262 |

18.5 |

3.0 |

3000/20 |

7650 |

120 |

| 2200/8 |

3682 |

24.6 |

3000/22 |

8250 |

132 |

| 2200/10 |

4102 |

30.8 |

3000/24 |

8850 |

144 |

| 2200/12 |

4522 |

36.9 |

4.0 |

3000/26 |

9450 |

156 |

15 |

| 2200/14 |

4942 |

43.1 |

3000/28 |

10050 |

168 |

| 2200/16 |

5362 |

49.3 |

5.5 |

3000/30 |

10650 |

180 |

|

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us