Product Brief

YPG series Pressure spray (granulation) drier it is a group can be accomplished simultaneously drying and granulation apparatus. According to process requirements can adjust the feed pump pressure, flow rate, the size of the orifice, and the desired size by a certain proportion of spherical particles.

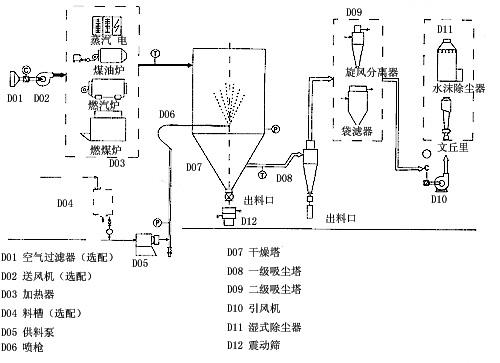

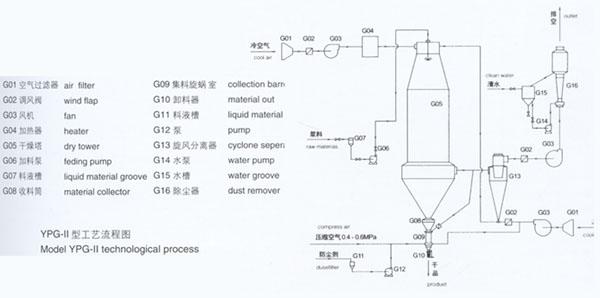

YPG series Pressure spray (granulation) drier group work process feed liquid through the high-pressure diaphragm pump input, discharge or mist, and then decreased with the flow of hot air, most of the particles were collected from the bottom discharge opening, and the exhaust gas fine powder through a cyclone separator, the exhaust gas discharged from the exhaust fan, the powder was collected by a cyclone located in the lower end of the cylinder pollination, at the outlet of the fan can also be equipped with two dust removal device, the recovery of more than 96-98%.

Tower YPG series Pressure spray (granulation) drier group with material contact parts, pipes, separator material, are used SUS304 production. Between the tower and the interior of the housing there is enough insulation, filler material is ultra-fine glass wool, with observation tower doors, mirrors, lighting and control instruments, the electrical control console control and display.

The heat source device YPG series Pressure spray (granulation) drier group heated by steam or electric heater, easy to operate, quick start, compact, clean, clean hot air and so on. Further control in the electrical control cabinet is equipped with an electric heater regulator, the inlet temperature stepless adjustment. The lack of electricity can be used for heating or steam coal, oil Hot blast stove, etc., partially or completely replace the electric heating devices. The factory will provide according to the actual needs of users of various heating methods.

Features

YPG series Pressure spray (granulation) drier drying speed, greatly increasing the surface area of the material after the liquid is atomized in a stream of hot air, can be evaporated instantly 95-98% moisture, to complete the drying time is only ten seconds to tens of seconds, and is particularly suitable for drying heat sensitive materials.

The resulting product is spherical particles, uniform size, good mobility, good solubility, high purity and good quality.

YPG series Pressure spray (granulation) drier wide range, depending on the characteristics of materials, can also be dried by hot air with cold air granulation, strong adaptability of the materials.

Simple stable, easy to control, easy to achieve automatic operation of.

Applications Chemical: organic catalyst, resin, synthetic detergent, oil, ammonium sulfate, dyes, dye intermediates, white carbon black, graphite, ammonium phosphate and the like.

Food: amino acids and the like, seasonings, protein, starch, dairy products, coffee aspirate, fish, meat and other fine.

Pharmaceuticals: medicine, pesticides, antibiotics, medical drinking and so on.

Ceramics: magnesium oxide, clay, metal oxides, dolomite.

Spray granulation: all kinds of fertilizer, aluminum oxide, ceramic powder, pharmaceutical, heavy metallic super hardness steel, chemical fertilizer, granular detergent, medicine and so on.

Spray cooling granulation: amino fatty acid, paraffin wax, glycerate, tallow and the like.

Aspect spray crystallized, the spray concentration and spray reactions are often used.

working principle

Process

Technical Parameters

|

Model

Item

|

YPG-25

|

YPG-50

|

YPG-100

|

YPG-150

|

YPG-200

|

YPG-300

|

YPG-500

|

YPG-1000 ~ 2000

|

|

Evaporation capacity kg / h

|

25

|

50

|

100

|

150

|

200

|

300

|

500

|

The index is determined according to the actual situation

|

|

Diaphragm

|

Power kw

|

0.35

|

4

|

7.5

|

11

|

15

|

22

|

30

|

|

Pressure Mpa

|

According to the experimental results in the material between 0.6 to 5 adjustment, the general operating between 1 and 3.

|

|

Tower diameter mm

|

1300

|

1800

|

2400

|

2600

|

2800

|

3200

|

3800

|

|

Equipment total height mm

|

7800

|

9200

|

11600

|

14000

|

15300

|

17100

|

19000

|

|

Electric heating Kw

|

75

|

120

|

150

|

At temperatures below 200 degrees, particularly in real terms

|

|

Steam + electricity Mpa + Kw

|

0.5 + 54

|

0.6 + 90

|

0.6 + 108

|

|

Hot blast stove Kcal / h

|

100 000

|

150,000

|

200 000

|

300,000

|

400,000

|

600 000

|

1000000

|

|

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us

中文版 |

中文版 |

ENGLISH |

ENGLISH |

Contact us

Contact us